Industry 5.0: How Man and Machine Can Co-Exist

During my time at Universal Robots, industry-wide discussion centered around Industry 4.0. Coined by Siemens, Industry 4.0 is about using information technology to optimize production processes and flows. The ultimate goal is the “lights out” factory – one that produces products around the clock without the need for humans.

It seemed to me, however, that Industry 4.0 thinking misses the point of manufacturing: creating value for the customers.

The problem with focusing too much on optimization and cost reduction is that it will actually mostly kill profit margins over time.

Focusing on building value with customers – through the creation of premium, unique products for which consumers will pay more – allows you to increase profits over time, as well as grow your business and thus hire more people.

A new way of thinking: Consumers’ need for unique products

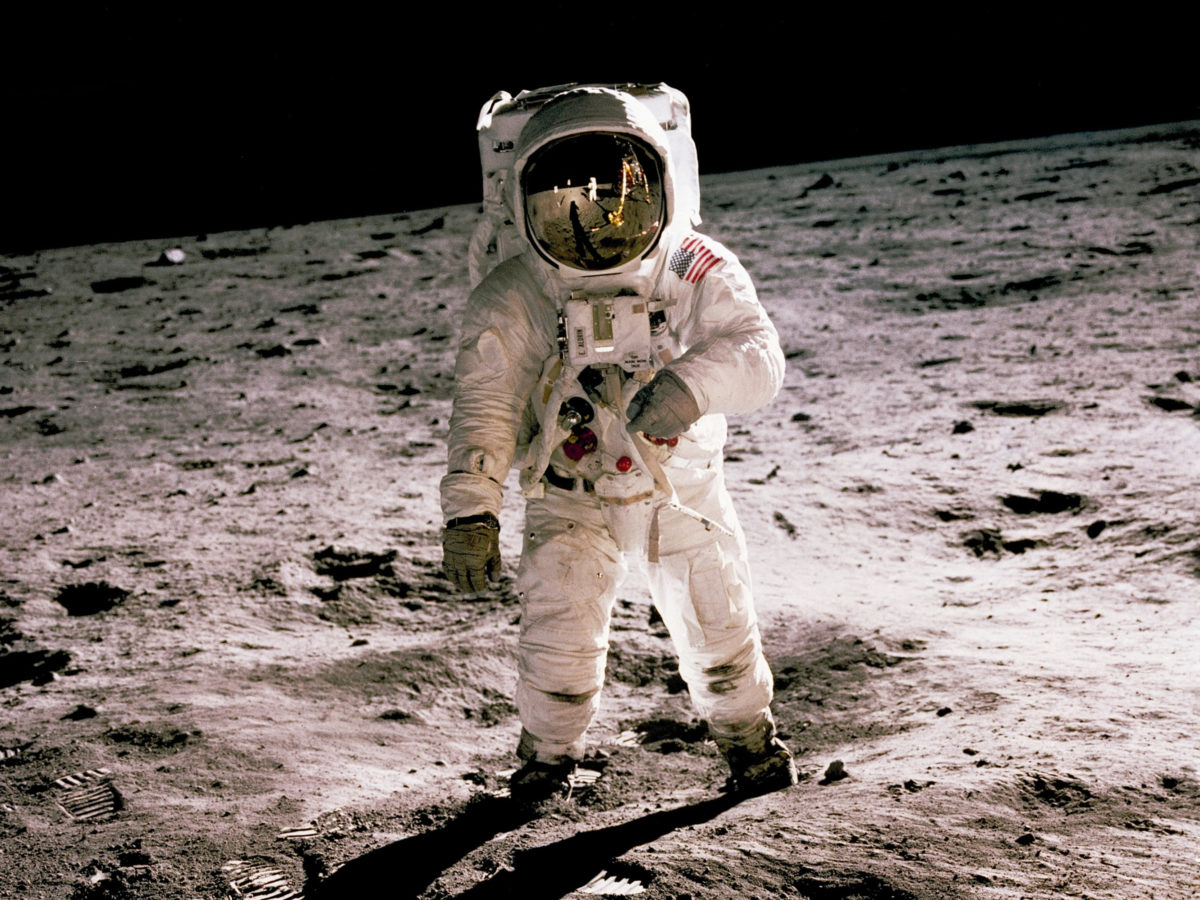

Industry 5.0 is the term I created to describe this idea of looking beyond cost reduction to focus on creating value. It’s human ingenuity that creates the machines that solve real problems. Only humans can tap into what other humans value and desire – machines can’t know what we think or want because they only do what we tell them to.

While the idea of Industry 5.0 embraces handcrafted products or adding the human touch to processes, it’s not a path back to pre-Industrialization.

For example, automation and all its benefits is necessary when creating vehicles. Building each vehicle by hand would result in low-quality, high-cost cars. We need automation to produce standard quality levels and to produce the vehicles efficiently and with less wear and tear on the human body.

Industry 5.0, however, recognizes that while consumers want a well-made industrial quality product, they don’t want a stock product. They want to buy something that makes them feel special, that expresses who they are as people, and they’re willing to pay premium for such products.

Manufacturers who easily and quickly modify their production lines using flexible automation such as collaborative robots to adapt to a changing market and/or consumers’ preferences will win.

We saw this truth play out time and again at Universal Robots. The small companies that purchased our robots ended up hiring more people. At first thought, it’s somewhat counter intuitive that more robots also mean more people, but at second thought, it makes perfect sense. The more efficient a company became due to using automation, the more it grew and the more people it needed to do the increased amount of work. As businesses thrive and grow, they hire more people.

Man and machine working together

The fallacy with Industry 4.0 is that you simply can’t remove low-skilled people and replace them with machines. Not only does it lower morale across the company, but it also eliminates years of product knowledge and craftsmanship that the line workers have.

Experienced workers know the materials, the processes, and the little tricks to creating value for a company. Ask any factory worker for an idea on how to improve a process and he or she will come back with multiple ideas.

It’s these people that need automation to free them from the drudgery of working like a machine so they can implement their value-creating ideas instead.

Where Industry 4.0 is about automating everything and removing humans, Industry 5.0 is about keeping the lights on and combining humans and machines on the factory floor.

Once a factory moves to “lights out,” value creation ends. Products become a commodity and the race to the bottom begins. While a company can squeeze out profits for a short while, in the long term it loses because consumers will move on to the premium products.

It’s the premium products with their unique “cool factor” that become the cash cows. The more consumers understand a product has the “human touch” added to it, the more they’re willing to pay for it. Consumers can sense how much passion and love goes into a product – whether it’s organic bedding, “build your own” vehicles, or artisanal food products.

For companies on the Industry 5.0 journey, it’s about using machines to reduce costs and improve production in order to free up their craftspeople to produce the “handcrafted” products consumers desire.

Filed under:

Michael Rada

Dear Mr. Østergaard, why do you name yourself creator of the name of INDUSTRY 5.0 when you came with the name half-year later than I did and during the “development process” you have just rob my words and turned it to match your production.

I hope everybody will check the truth and hope INDUSTRY 5.0 will never become a sales tool as INDUSTRY 4.0 did.

I informed you about the origin of the word INDUSTRY 5.0 several times, you never replies, which prove the reality.

Esben Hallundbæk Østergaard

Hi Michael

Well, it’s not so surprising that Industry 5.0 is the successor to Industry 4.0 😉 I think it is the content of Industry 5.0 that is the interesting part. From my work as founder and CTO of Universal Robots, I could see how robot created jobs rather than taking jobs, and how companies who adopted flexible automation managed to grow their business. It made me think a lot about industrial value creation and the journey that humanity is on with technology, and that is what created my thoughts on Industry 5.0. I don’t know who came first, but I did work on it for some time before I talked about it for the first time (I think it was in 2012). If we both got the same idea it is not surprising to me. From my years in science, I could see how similar ideas tended to pop up around the same time. Probably something in the ripeness in our common culture for new ideas to emerge. The whole idea behind Universal Robots was to empower people, to use automation as a tool to do their work more efficiently, and that was the intention from the beginning.

Brianchund

Thanks with regard to providing this kind of terrific knowledge.

JamesItexy

Really wished to stress I’m ecstatic I came onto your site!